All Axis Machining was formed out of the need to provide OEM design companies with access to high-quality metal fabrication services and thermal managements products such as heatsinks, thermal interface materials and thermal analysis software. Traditionally, it has been difficult for OEM design companies to find available capacity (especially large format parts) on 5-Axis and even 11-Axis machines CNC’s and Lathes to develop and produce their parts.

In 2007, All Axis Machining was formed to provide a single point system where companies could access high end equipment and manufacturing systems needed to develop and produce not only their most complex parts, but their need for any type of metal fabrication requirements.

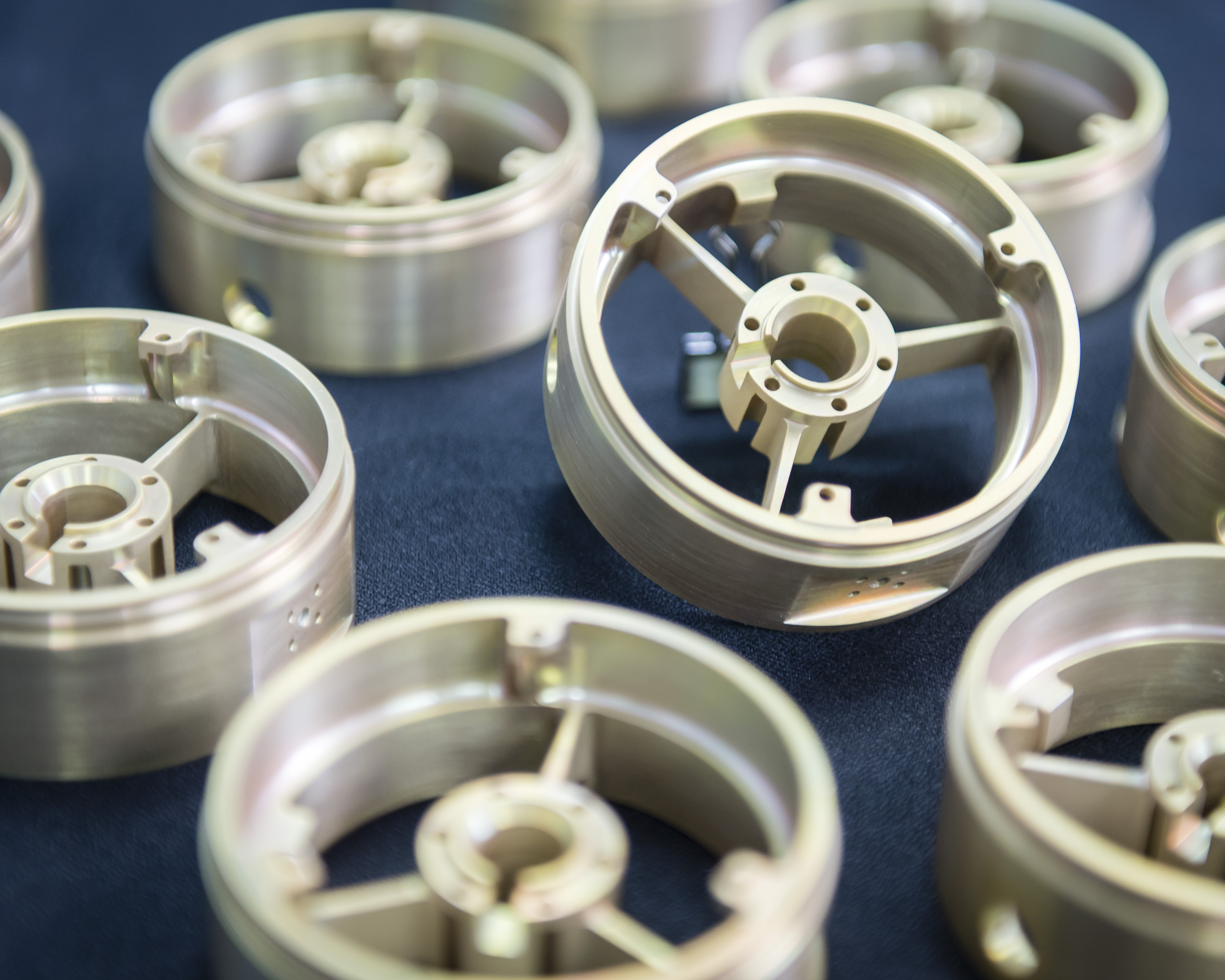

Today, this single factory has the capability of delivering finished products (from small to very large formats) manufactured from a variety of manufacturing techniques including, but not limited to CNC Machining, Wire and Sinker EDM, Extrusions, Stampings, and Punching in a variety of material from Steel, Aluminum, Plastics and composite materials.

What uniquely sets us apart from other machining suppliers is our one-setup approach to manufacturing (1 Cycle/1 Part Output). This is accomplished through the acquisition of highly advanced and accurate automated machinery. This helps to reduce lead time and respond to our customer’s spike demands.

In addition, to maximize the equipment utilization and internal capacity, the entire factory is driven by a fully integrated MRP system. This allows us to see the status of every job as it makes its way through the manufacturing department.

Our strengths (your benefits) lie in our people. All Axis Machining provides a highly-trained and motivated team of professional machinists and fabricators that want to see your company succeed. It is our philosophy that an organization can only be as good as its employees. We are committed to training, developing, and empowering our employees to create competitive advantages for our customers. Virtually all our employees are occupationally multi-dimensional. We also support and have adopted internal policies that encourage our employees to maintain emotionally & fiscally strong families. Last year alone, we spent many hours of training them to ensure our employees are at their maximum performance and readiness.

All Axis Machining continues to invest in new machines to provide you with access to more manufacturing capabilities. We also provide Turn-Key Mechanical Assemblies. So, whether you are looking for prototypes or medium to large runs, we can help you based on your project demands. Give us a call today to get started with your new project.

Our company objectives are straightforward:

-

Manufacture quality products, on time and at a reasonable price to all customers.

Our expert and dedicated staff understand how important your project is to you and from concept to completed job, we’re here to make it happen. Our staff of QA inspectors works in conjunction with our machining staff to develop a robust machining process plan for every product that is released to the production floor. Together, they ensure the CNC CAD/CAM programmed tool path is optimized for speed and accuracy, the material choice is compliant with the customer’s design requirements, the first article meets the customer’s engineering drawing tolerances and production parts run within specific process controls.

-

Provide engineering and manufacturing support.

We know that our customers depend on us to be the machining and fabrication experts and that is why we provide initial “Design for Manufacture” consultation upon request. This process routinely results in a more robust design, reduced manufacturing time and a more cost effective component. Finally, the QA team completes a Final Inspection to verify the process is compliant with our customer’s design and within upper and lower control limits.

We can even provide full reverse engineering services for those parts where manufacturing prints, for legacy products, have been lost or where other manufacturers have either discontinued their products or gone out of business.

-

Complete customer production support

Providing support in accordance with our customers business models and Supply Chain Management mandates. We recognize that each customer has defined unique procedures manufacturing plans that are individually unique to their success.

A few ways that we support our current customer base are as follows:

Manufacturing:

- Engineering prototype Support (we routinely build evaluation units from 1- 50 pieces)

- Initial low volume / pilot production runs (we routinely process orders from 50 – 1K pieces)

- Full production runs (we regularly ship with some customer anywhere from 25 to 125,000 pieces per year or more)

Supply Chain:

- Stocking Release Programs (Blanket Orders)

- Kanban Lean Manufacturing

- Contract Manufacturing Support (EMS – Electronics Manufacturing Services)

Regulatory Compliance & Certifications:

- Rohs Compliance

- Conflict Mineral Compliance

- AS9102 Certified

- ITARS

- ISO Certified

-

Make our customer competitive.

We understand that for us to be successful, that our customers to be successful and they need to be competitive. This is why we will work with our customers to find ways to lower the cost of their projects. This could involve working with their engineering to redesign the parts to relaxing tolerances.

-

Support End of Life and Repairs

We understand that in certain circumstances that there some of our customers, whether through company culture and/or contractual obligations, must provide repair support their legacy equipment. It is our stated objective that we will support these programs as part of our general business philosophy.

We will attain this perpetual goal through continuous improvement in each essential aspect of long-term business relationships, quality assurance, product delivery, communication, product innovation, custom processes, consultation, support, trust and teamwork ... all culminating with the achievement of excellence.

AT-A-GLANCE FactSheet

| MFG HEADQUARTERS: |

All Axis Machining

4825 Top Line Drive Dallas, TX 75247 |

| REMIT ADDRESS: |

804 Port America PL

Grapevine, TX 76051 |

| FACILITY SIZE: | 20,000 Square Feet |

| TYPE OF BUSINESS: | Manufacturer |

| TELEPHONE NUMBER: | 972 312 8609 |

| INTERNET ADDRESS: | www.allaxismachining.com |

| YEAR INCORPORATED: | 2007 |

| NAICS: | 332322; 332710, 331316, 332116, 332510, 332999, 333511, 333514 |

| SIC CODE: | 3444, 3469; 3471, 3499, 3354 |

| CERTIFICATIONS: | AS9100D, ISO-9001:2015, ITAR Registered |

| STANDARD TERMS: |

Selling Terms and Conditions

Vendor Purchase Orders Terms and Conditions |

| SHIPPING: | Worldwide |

| GENERAL CAPABILITIES: | 5-Axis CNC Machining, 11-Axis CNC Turning, Aluminum Extrusions, Stampings, Assemblies, Hardware, Screw Machine; Assemblies, Silk Screening Laser Engraving, CMM Inspection, Metal Sawing |

| INDUSTRIES SERVING: | Electronics, Industrial, Communications, Medical, Aerospace Defense, Scientific, Retail / POS, Commercial, Computers, LED Lighting; Energy (Solar, Oilfield); Space Exploration (Rocket Components); Satellite Parts. |

| STANDARD PRODUCTS: | Heatsinks (Extruded, Stamped, Skived, Copper, Aluminum and Heatpipes); Thermal Interface Materials, Enclosures (NEMA, 1U, 2U, 3U & 4U); Front Panels |

|

CUSTOM PRODUCTS:

(BUILD TO PRINT) |

Plastic Insulators, Silicone Molding, Custom Heatsinks, Enclosures, LED Support; Gimbals, Microwave Housings, Waveguides, Hardware, EMI/RFI Shielding, Buss-Bars, Handles, Springs |

| CONTRACT SERVICES: | CMM Inspection with AS9102 Report; Metal Sawing Services;EDM (Wire & Sinker); Engraving; Thermal Analysis; Reverse Engineering; Silk Screening; Powder Coating |

AS9100D and 9001:2015 CERTIFIED

Why AS9100D and ISO 9001:2015 certifications gives our customers the highest level of confidence:

As an aggressive partner in a global market, All Axis Machining is very proud to have achieved AS9100D and ISO 9001:2015 certifications. What this achievement represents to our customers is that All Axis Machining has attained conformance to the International Organization for Standardization’s (ISO) requirements for production and service standards. This accomplishment is reserved for a small number of highly competitive corporations, and it is what this achievement represents to our customers that matters most.

What the AS9100D and ISO 9001:2015 certifications actually means to our customers:

Our AS9100D and ISO 9001:2015 certifications are not intended to measure product quality, but these certifications do let our customers know that All Axis Machining has systems, processes, and procedures in place that will positively impact the quality of our products and services. These systems, processes and procedures impact every facet of our business, and through ongoing ISO auditing, our customers can feel confident that these standards that effect product quality are being continuously reviewed, and improved.

Our ongoing commitment to quality:

All Axis Machining takes great pride being recognized as an AS9100D and ISO 9001:2015 registered company. These certifications represent recognition of the quality first commitment that drives our company. For our customers, this represents another step in our commitment to providing the highest level of quality products and service in the future.

ITARS COMPLIANT / REGISTERED

The U.S. Government requires all manufacturers, exporters, and brokers of defense articles, defense services, or related technical data to be ITAR (International Traffic in Arms Regulations) compliant.

Many All Axis Machining’s customers are manufacturers, exporters, and/or brokers of defense articles, defense services or related technical data and as such are required by the U.S. Department of State to be registered with the Directorate of Defense Trade Controls (DDTC) to be ITAR compliant. Language often contained in their contracts, on purchase orders and request for proposals require that their suppliers also be ITARS compliant.

All Axis Machining has responded to this specific flow down requirements, by applying for and receiving the necessary compliance documentation certifying that it is ITARS compliant.

| NAICS 6-Digit Code | North American Industry Classification System Title |

|---|---|

| 332322 | Sheet Metal Work Manufacturing |

| 332510 | Hardware Manufacturing |

| 332312 | Fabricated Structural Metal Manufacturing |

| 332313 | Plate Work Manufacturing |

| 332323 | Ornamental and Architectural Metal Work Manufacturing |

| 332812 | Metal Coating, Engraving |

| 332999 | All Other Miscellaneous Fabricated Metal Product Manufacturing |

| 333511 | Industrial Mold Manufacturing |

| 333514 | Special Die and Tool, Die Set, Jig, and Fixture Manufacturing |